Full Vacuum Degassing Kits – Ready to Plug in and Go

Degassing Kits

Degassing Kits

Features & Specifications

- Complete Degassing Kits: Our kits are meticulously curated to include a mild steel degassing chamber and a high-quality DVP vacuum pump, along with all the necessary connection nozzles.

- Choose Your Pump: For those who need to reduce degassing time, an upgrade to a more powerful vacuum pump is available.

- Peace of Mind: Both the degassing chambers and the vacuum pumps are backed by a 12-month warranty, ensuring long-lasting performance and reliability.

Important Considerations for Degassing

- Water-Based Mixtures: Be aware that degassing water-based mixtures (such as plaster, acrylic, or refractory cements) can cause issues with water vapor mixing with the vacuum pump oil. For continuous degassing of these materials, we offer specialized pumps and equipment to address these challenges. Please contact us for expert advice.

- Chamber Capacity: The physical volume of the chamber is not equal to the liquid capacity you can degass. Liquids often expand significantly (up to 4-5 times their initial volume) during the degassing process. To prevent overflow, use a suitable mixing container inside the chamber that allows ample space for this expansion.

All degassing chambers and vacuum pumps are supplied with a 12 month warranty.

See Degassing Chambers page for recommended working capacities.

3 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP3K4

The DP3K4 kit will comprise the following:

- A 3 litre steel degassing chamber (see Degassing Chamber page for full specification)

- A LC.4 rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 18 secs.

9 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP9K4

The DP9K4 kit will comprise the following:

- A 9 litre steel degassing chamber (see Degassing Chamber page for full specification)

- A LC.4 rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 45 secs.

9 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP9K8

The DP9K8 kit will comprise the following:

- A 9 litre steel degassing chamber (see Degassing Chamber page for full specification)

- An LC.8-AVE rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 23 secs.

27 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP27K8

The DP27K8 kit will comprise the following:

- A 27 litre steel degassing chamber (see Degassing Chamber page for full specification)

- An LC.8-AVE rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 73 secs.

27 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP27K12

The DP27K12 kit will comprise the following:

- A 27 litre steel degassing chamber (see Degassing Chamber page for full specification)

- An LC.12 rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 49 secs.

42 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP42K12

The DP42K12 kit will comprise the following:

- A 42 litre steel degassing chamber (see Degassing Chamber page for full specification)

- An LC.12 rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 79 secs.

42 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP42K25

The DP42K25 kit will comprise the following:

- A 42 litre steel degassing chamber (see Degassing Chamber page for full specification)

- An LC.25 rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 38 secs.

76 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP76K25

The DP76K25 kit will comprise the following:

- A 76 litre steel degassing chamber (see Degassing Chamber page for full specification)

- An LC.25 rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 68 secs.

76 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP76K40

The DP76K40 kit will comprise the following:

- A 76 litre steel degassing chamber (see Degassing Chamber page for full specification)

- An LC.40 rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 43 secs.

118 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP118K25

The DP118K25 kit will comprise the following:

- A 118 litre steel degassing chamber (see Degassing Chamber page for full specification)

- An LC.25 rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 106 secs.

118 LITRE VACUUM DEGASSING CHAMBER KIT – MODEL DP118K40

The DP118K40 kit will comprise the following:

- A 118 litre steel degassing chamber (see Degassing Chamber page for full specification)

- An LC.40 rotary vane oil vacuum pump (see Vacuum Pumps page for full specification)

- Mains cable fitted with a choice of UK 3 pin plug (standard) or European style 2 pin plug (to be specified when ordering).

- 2 metres of clear wire reinforced plastic vacuum hose together with hose clips.

- Vacuum pump oil.

- Instructions

Approximate pump down times using this combination of chamber and pump based on a clean and empty chamber to a pressure of 2mbar (29.9 inches Hg) is 66 secs.

Optional Extras

Degassing Chamber Wheel Kit & Replacements

Wheel kits are included for the larger size vacuum degassing chambers (our DP76 and DP118 chambers). The wheels are rubber coated, swivel and lockable.

Please inform us when you are are ordering if you would like the wheel Kit included on another vacuum chamber.

The Wheel kit includes all fixings.

Part No. WH-76-KIT

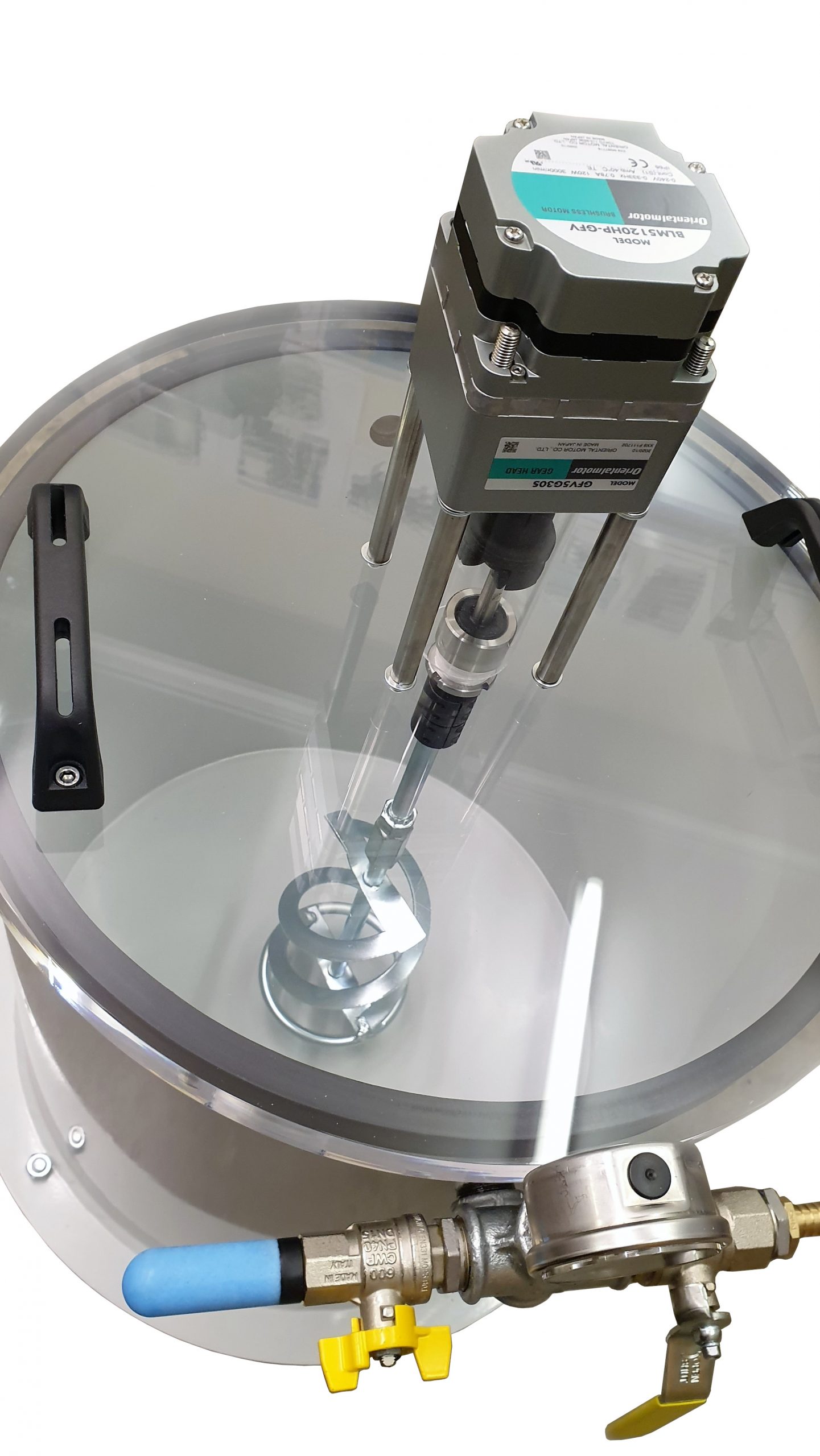

Through The Lid Motorised Stirrer

AVE’s variable speed motorised vacuum paddle stirrer is available as a direct replacement for the 42, 76 and 118 litre degassing chamber lid, with a separate control unit.

Part Numbers:

42 litre stirrer DP42-STIR-20

76 litre stirrer DP76-STIR-20

118 litre stirrer DP118-STIR-20