Our Range of Stock Vacuum Chambers

Degassing Chambers

Degassing Chambers

AVE offer a comprehensive range of professionally manufactured high specification degassing systems for the removal of air bubbles from Silicone Rubbers, Resins, Plaster, Epoxies etc and for the removal of air trapped within intricately shaped moulds.

The degassing chambers are constructed from mild or stainless steel and are normally powder-coated inside and out, depending on customer requirements and application.

All models are fitted with a side mounted manifold that includes –

- Gas rated nickel plated ball valves for vacuum isolation and air admittance.

- High quality vacuum dial gauge (Bourdon tube), 63mm diameter. Dual display -1…0 bar & 0…-30 inHg. Liquid filled to prevent needle bounce. Gauge accuracy class 1.6. Laminated safety glass. Stainless Steel body.

- Air admittance adjustable restriction valves fitted on the smaller models.

If you require a bespoke chamber please contact us with your specific requirements.

1.5 LITRE VACUUM DEGASSING CHAMBER – MODEL DP1.5

The DP1.5 chamber will comprise:

- A welded mild steel chamber measuring 156mm internal diameter and 72mm internal height.

- Side mounted 1/4″ BSP manifold.

- Nickel plated hose nozzle to accept 10 mm bore hose.

- Recommended maximum working capacity 250ml.

- Weight 3.8kg.

- Instructions.

Note – This chamber is also available as a kit to include a suitable vacuum pump, vacuum hose and all appropriate hose connections. See the degassing kits page for more details.

Note – This chamber has been discontinued from stock, but can still be made to order if required.

3 LITRE VACUUM DEGASSING CHAMBER – MODEL DP3

The DP3 chamber will comprise:

- A welded mild steel chamber measuring 156mm internal diameter and 155mm internal height.

- Side mounted 1/4″ BSP manifold.

- Nickel plated hose nozzle to accept 10 mm bore hose.

- Recommended maximum working capacity 500ml.

- Weight 4.8kg.

- Instructions.

Note – This chamber is also available as a kit to include a suitable vacuum pump, vacuum hose and all appropriate hose connections. See the degassing kits page for more details.

9 LITRE VACUUM DEGASSING CHAMBER – MODEL DP9

The DP9 chamber will comprise:

- A welded mild steel chamber measuring 206mm internal diameter and 270mm internal height.

- Side mounted 1/4″ BSP manifold.

- Nickel plated hose nozzle to accept 10 mm bore hose.

- Recommended maximum working capacity 2 litre.

- Weight 12kg.

- Instructions.

Note – This chamber is also available as a kit to include a suitable vacuum pump, vacuum hose and all appropriate hose connections. See the degassing kits page for more details.

27 LITRE VACUUM DEGASSING CHAMBER – MODEL DP27

The DP27 chamber will comprise:

- A welded mild steel chamber measuring 311mm internal diameter and 356mm internal height.

- A side mounted 3/8″ BSP manifold.

- 1/2″ BSP accessory port (blanked)

- Brass hose nozzle to accept 1/2″ mm bore hose.

- Recommended maximum working capacity 5 litre.

- Weight 22 kg.

- Instructions.

Note – This chamber is also available as a kit to include a suitable vacuum pump, vacuum hose and all appropriate hose connections. See the degassing kits page for more details.

42 LITRE VACUUM DEGASSING CHAMBER – MODEL DP42

The DP42 chamber will comprise:

- A welded mild steel chamber measuring 373mm internal diameter and 381mm internal height.

- A side mounted 1/2″ BSP manifold allows for larger vacuum pump options to be used.

- Brass Hose nozzle to accept 12 mm bore hose.

- Recommended maximum working capacity 10 litre.

- Weight 33kg.

- Instructions.

Note – This chamber is also available as a kit to include a suitable vacuum pump, vacuum hose and all appropriate hose connections. See the degassing kits page for more details.

76 LITRE VACUUM DEGASSING CHAMBER – MODEL DP76

The DP76 chamber will comprise:

- A welded Mild Steel chamber measuring 460mm internal diameter and 460mm internal height.

- Side mounted 3/4″ BSP manifold.

- Brass hose nozzle to accept 12 mm bore hose.

- Replaceable Nitrile rubber L shaped gasket.

- Recommended maximum working capacity 15 litre.

- Weight 45kg.

- Lockable swivel wheels fitted.

- Instructions.

Note – This chamber is also available as a kit to include a suitable vacuum pump, vacuum hose and all appropriate hose connections. See the degassing kits page for more details.

118 LITRE VACUUM DEGASSING CHAMBER – MODEL DP118

The DP118 chamber will comprise:

- A welded mild steel chamber measuring 500mm internal diameter and 600mm internal height.

- Side mounted 3/4″ BSP manifold.

- Brass hose nozzle to accept 12 mm bore hose.

- Recommended maximum working capacity 25 litre.

- Weight 64kg.

- Lockable swivel wheels fitted.

- Instructions.

Note – This chamber is also available as a kit to include a suitable vacuum pump, vacuum hose and all appropriate hose connections. See the degassing kits page for more details.

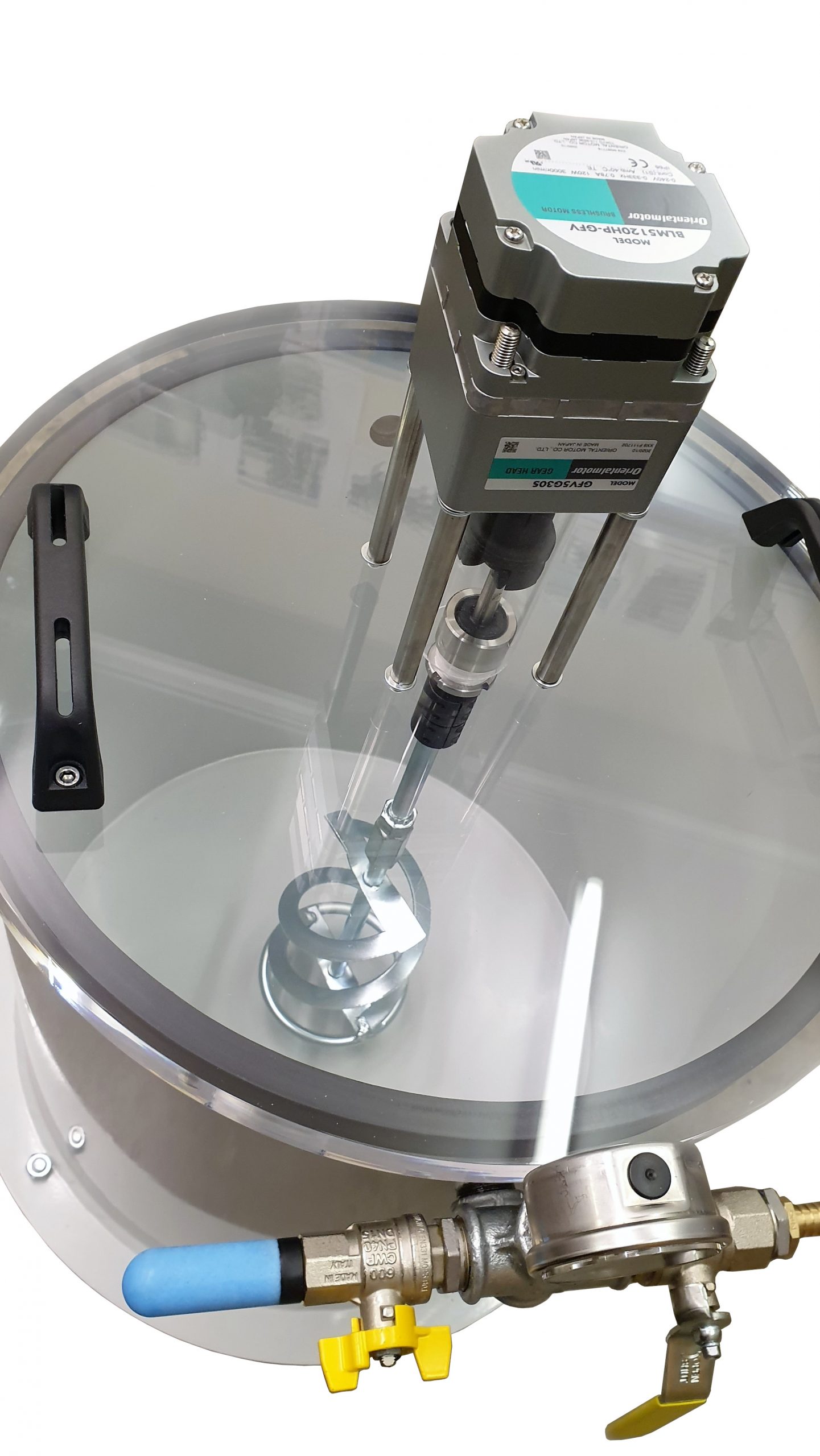

Through The Lid Motorised Stirrer

AVE’s variable speed motorised vacuum paddle stirrer is available as a direct replacement for the 42, 76 and 118 litre degassing chamber lid, with a separate control unit.

Part Numbers:

42 litre stirrer DP42-STIR-20

76 litre stirrer DP76-STIR-20

118 litre stirrer DP118-STIR-20

VACUUM DEGASSING CHAMBERS – FURTHER INFORMATION

Durable and Leak-Tight Degassing Chambers

Key Features and Manufacturing Process

- Lid Materials: We manufacture chamber lids from a range of high-quality materials to suit various applications, including clear cast acrylic, glass, aluminium alloy, or stainless steel. Metal lids can be equipped with a viewport for convenient viewing.

- Stress-Free Acrylic Lids: To ensure durability, all our acrylic lids undergo a temperature annealing process. This removes internal stresses that can occur during machining and polishing, preventing cracks and extending the lifespan of the lid.

- Precision-Machined Seal Faces: The open end of each chamber is carefully machined after fabrication to create a perfectly level and smooth seal face. This precision ensures an optimal surface for the seal.

- Reliable Sealing System: A nitrile rubber ‘L’ gasket provides a secure seal between the lid and the chamber, resulting in a completely leak-tight system.

- Rigorous Leak Testing: Each degassing chamber is fully leak tested multiple times—during manufacturing and again after painting—to guarantee its integrity and performance.

- Ready for Immediate Use: Chambers are shipped complete with all necessary seals and manifolds pre-fitted, meaning they are ready for immediate use upon arrival. Simply connect your hose and vacuum pump to get started.

All degassing chambers are covered by a 12 month warranty period.

All dimensions and size/volumes are approximate.

We understand that some applications require unique design solutions. If you can’t find the exact chamber you’re looking for in our stock products, please don’t hesitate to get in touch with us for a custom design.