Sometimes things don’t quite go to plan or plans change, but that is the best thing about engineering, you find a way to make things work and learn from mistakes.

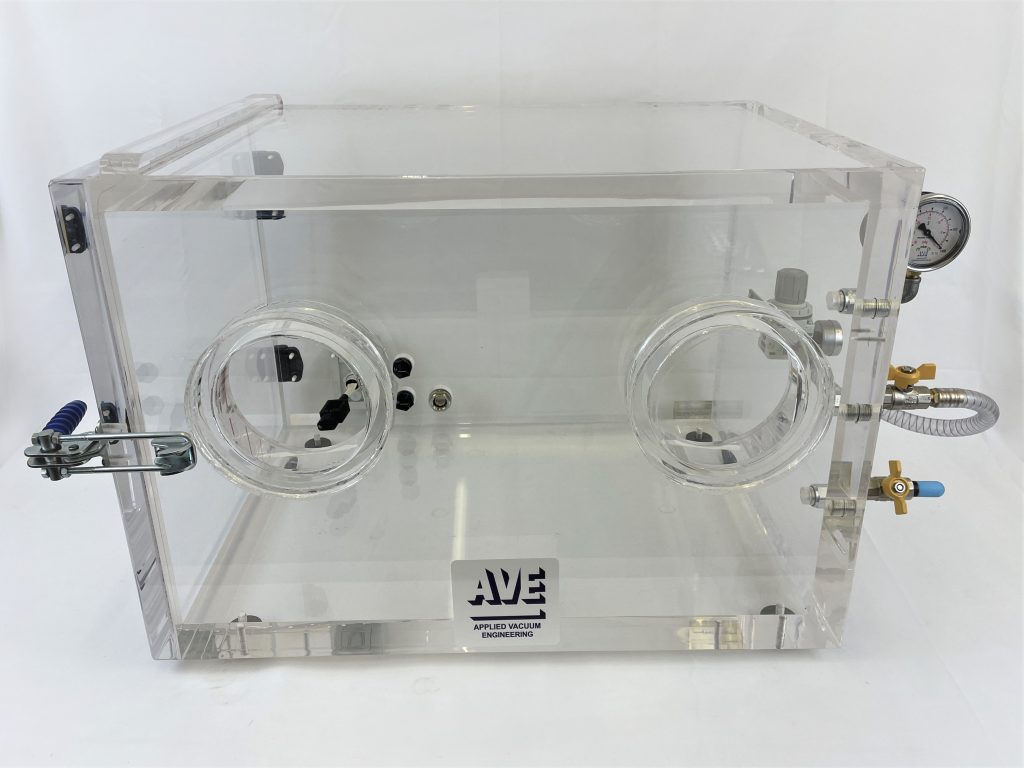

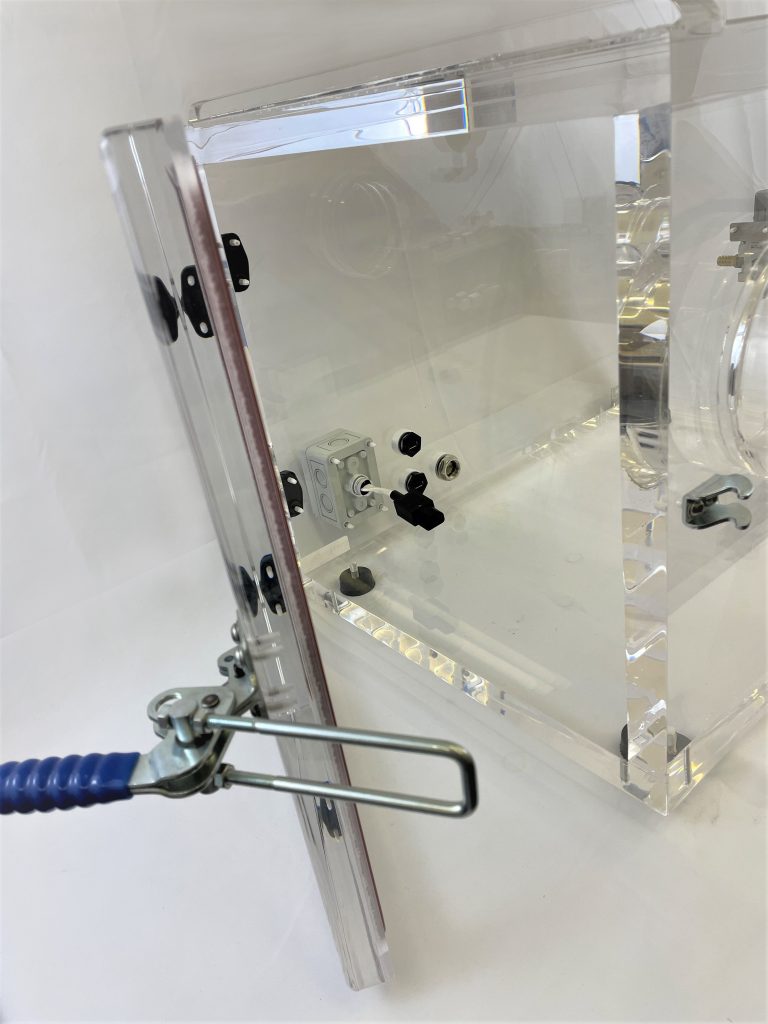

Originally this acrylic vacuum chamber was supposed to be working not much below atmospheric pressure and had gloves in to allow the user the ability to manipulate their product inside. However after a lot of changes and different pressure requirements (and a lot of broken gloves) it was decided the only way to achieve the desired manipulation inside the chamber was equalize the pressure inside and backfill with an inert gas, however they needed a specific value for absolute pressure so it wasn’t really an option. Instead we filled the holes in and they manufactured a clever little system of actuators to manipulate their cartridge under vacuum.

The final chamber is a bit of a Frankenstein box, but that’s okay, we live and learn and it does exactly what is needed of it, plus the 240V electrical power, 2 x USB and ethernet feedthroughs all work perfectly adding really nice functionality to this vacuum chamber.