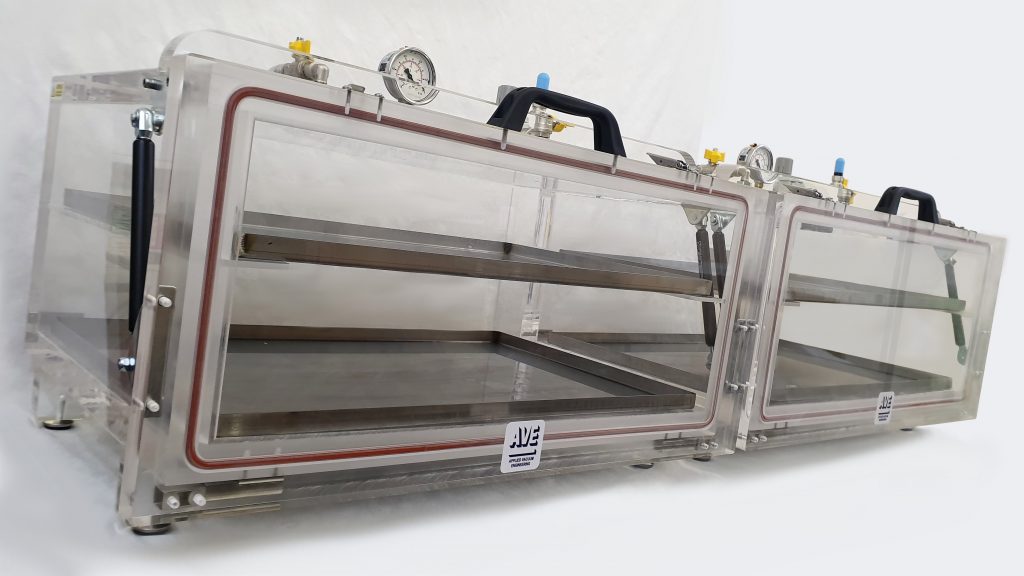

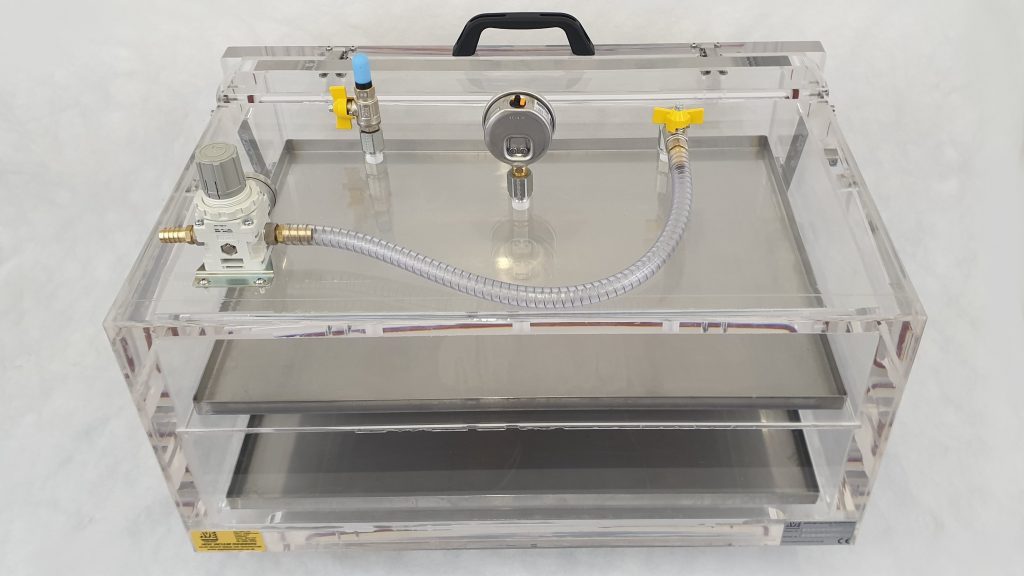

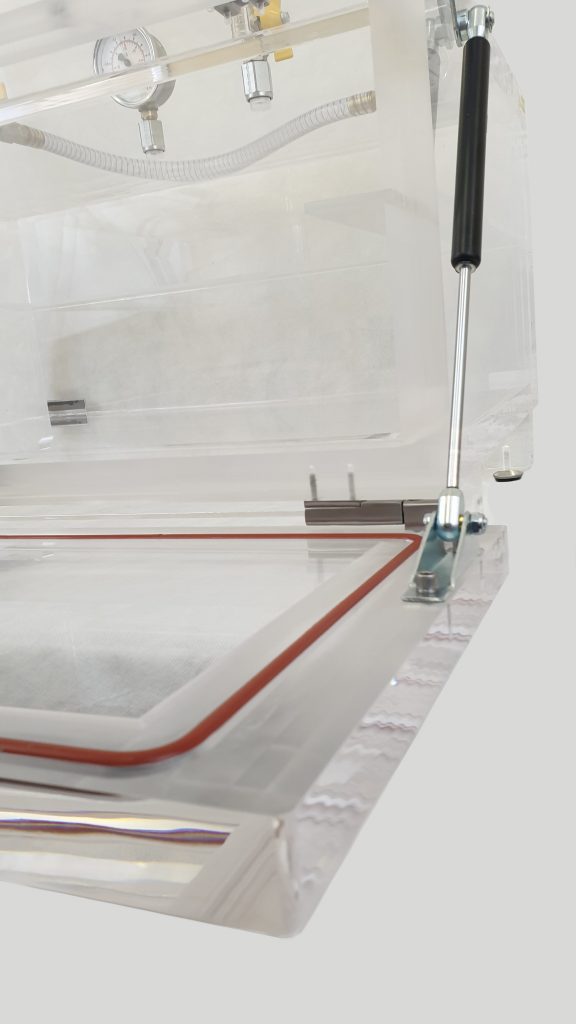

This acrylic package testing chamber was one of two designed around testing the seal integrity of the foil lid on a cartridge. The test rig holds around 50 cartridges and the operator needed good 360 degree view during the process.

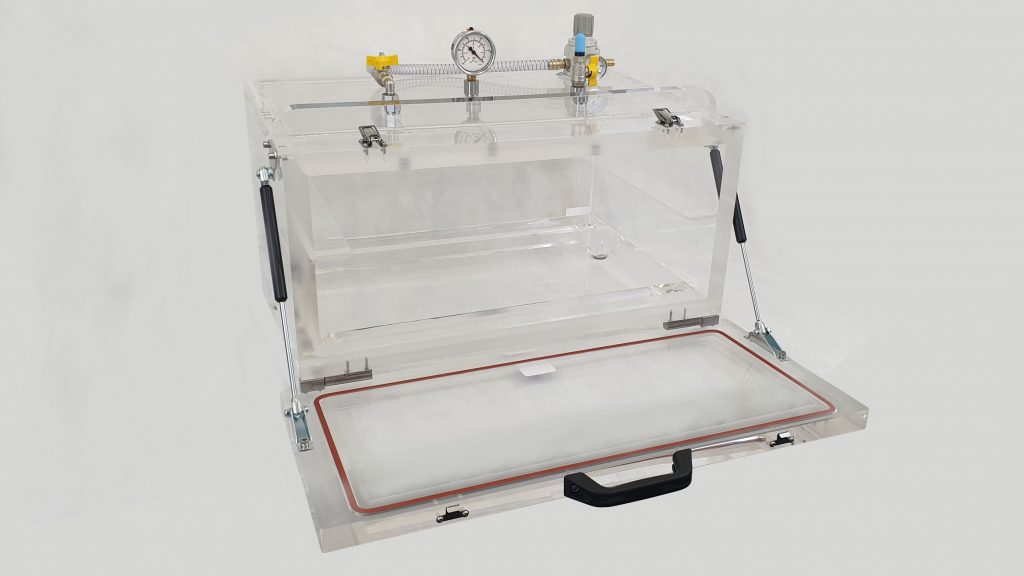

Acrylic vacuum chambers are ideal for applications like these, however this product has potentially dangerous chemicals inside and could harm the acrylic if there was a leak, in turn the material could haze over time and eventually compromise structural integrity of the entire vacuum chamber.

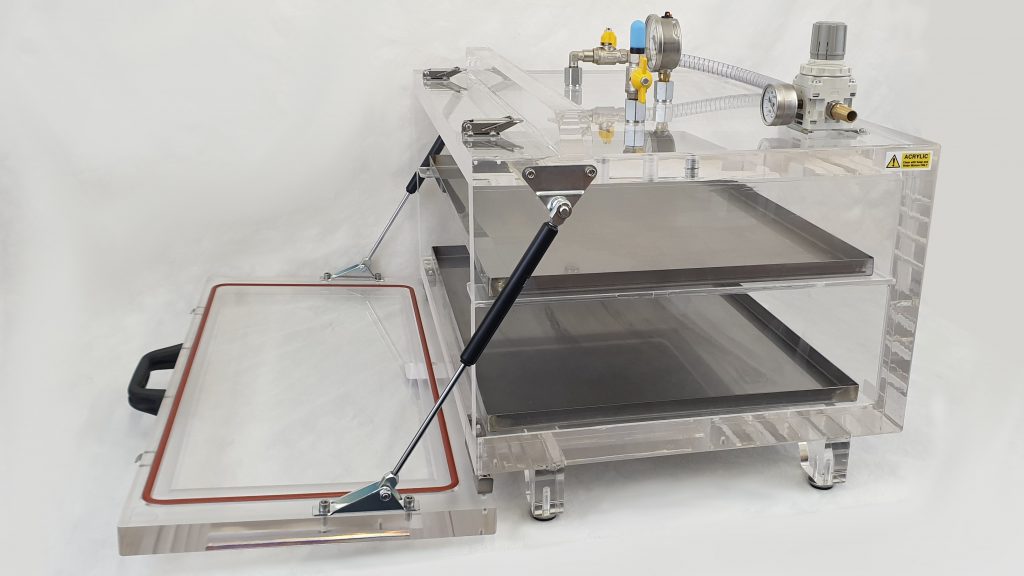

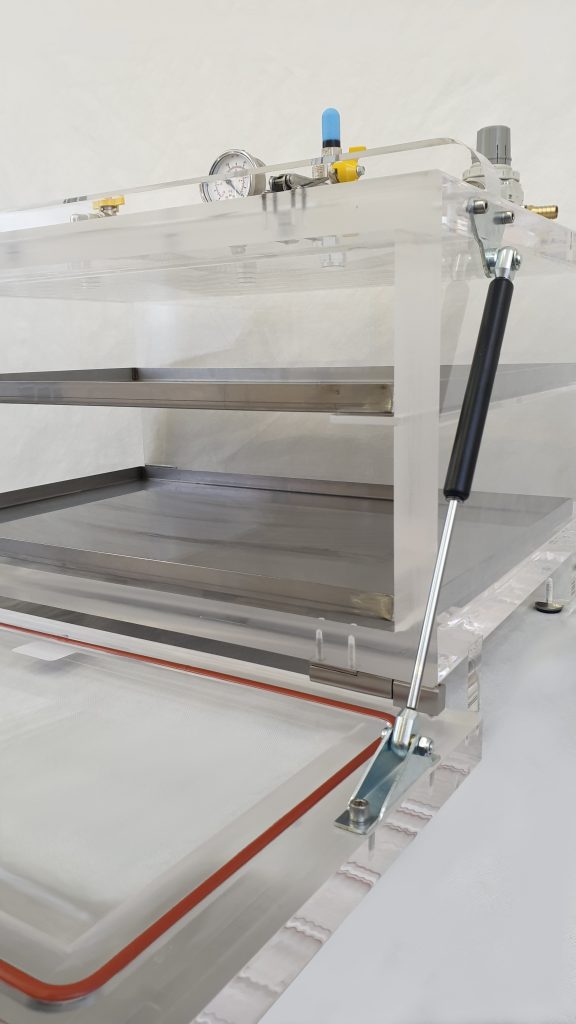

This led to some material testing and further measures to be put in place in terms of the 304L stainless steel drip trays to catch any leaks from any damaged cartridges.

A high throughput was also important to the customer, therefore the inclusion of a shelf meant that the capacity of the chamber was instantly doubled and paired with a DVP LC.12 which could complete the pumping down process in around a minute, meaning the operators could test thousands in a day.

DVP LC.12

These chambers were paired with two DVP LC.12 Vacuum Pumps which achieve an ultimate pressure of 2 mbar but regulated to the 175 mbar using the IRV20 vacuum regulator as desired by the customer.

AVE are the main UK sales and service center in the UK for DVP